Optical Alignment & LASER TRACKINg

Precision Alignment Services

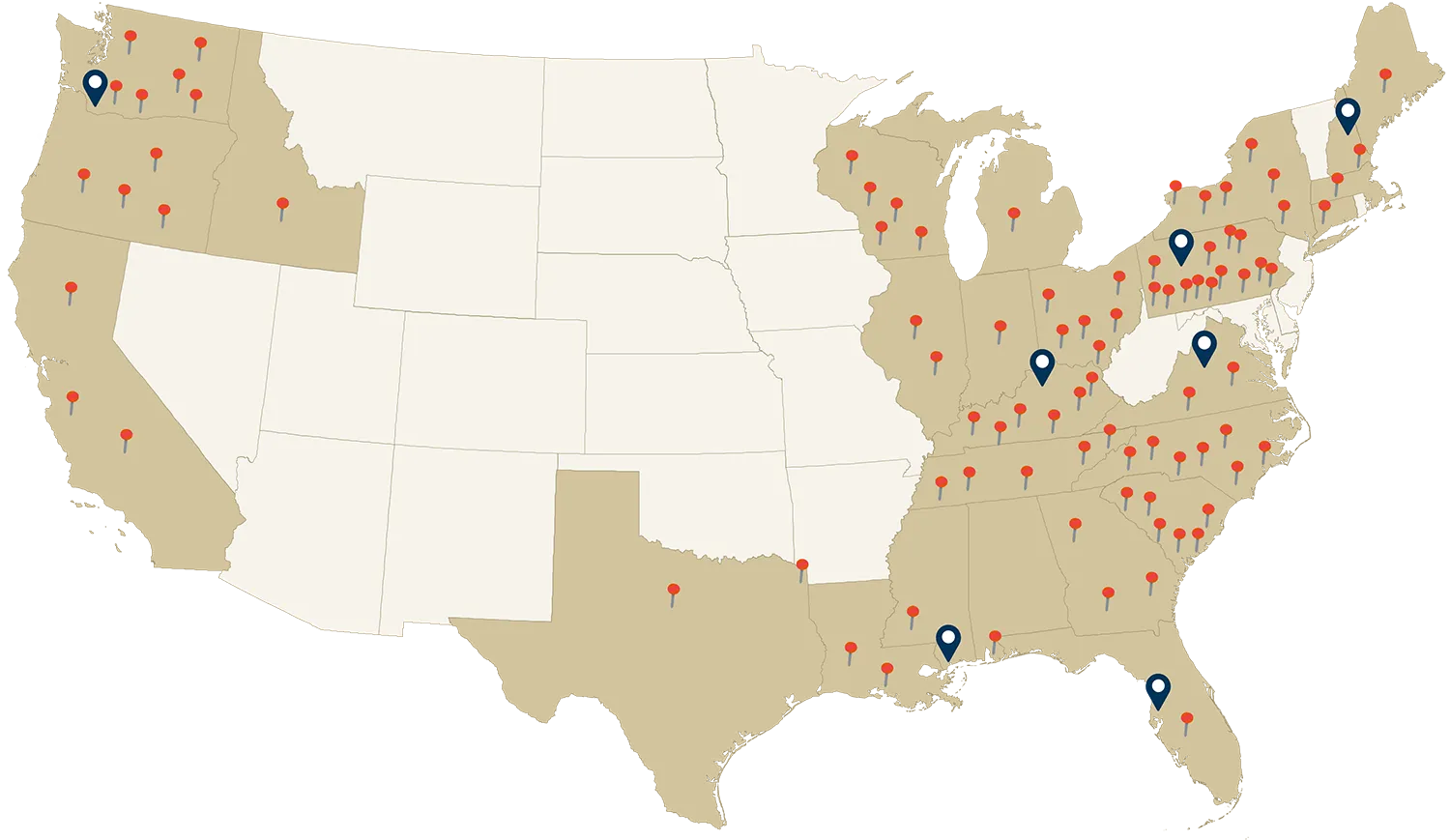

From new installations to re-builds, relocations, as-builts, and profiles Total Precision has the right team strategically placed throughout the U.S. serving all markets and regions competitively.

Optical Alignment Benefits:

Laser Tracking Advantages:

service related FAQ’s

We don’t take short-cuts—they’re a myth and result in compounding damages and expense. Our predictive maintenance approach follows proven procedures to identify issues early and prevent costly failures.

Proper alignment prolongs component life, reduces energy requirements, improves efficiency, and significantly reduces unplanned down-time, leading to better overall performance and lower operating costs.

Precision allows your components to run as efficiently as they are designed. Every .001″ beyond tolerance has a calculable impact on energy use, making precise alignment essential for reducing energy consumption and maximizing equipment performance.

Our services are based on standards and sorting that allow you to achieve improved safety, efficiency, and productivity across your manufacturing operations.

Following OEM procedures and tolerances are just as important as following the guidance of your Industry Associations. That data is tied directly to improved ROI and Product Quality.