Alignment & Precision Services

LIDAR COLLECTION AND PROCESSING

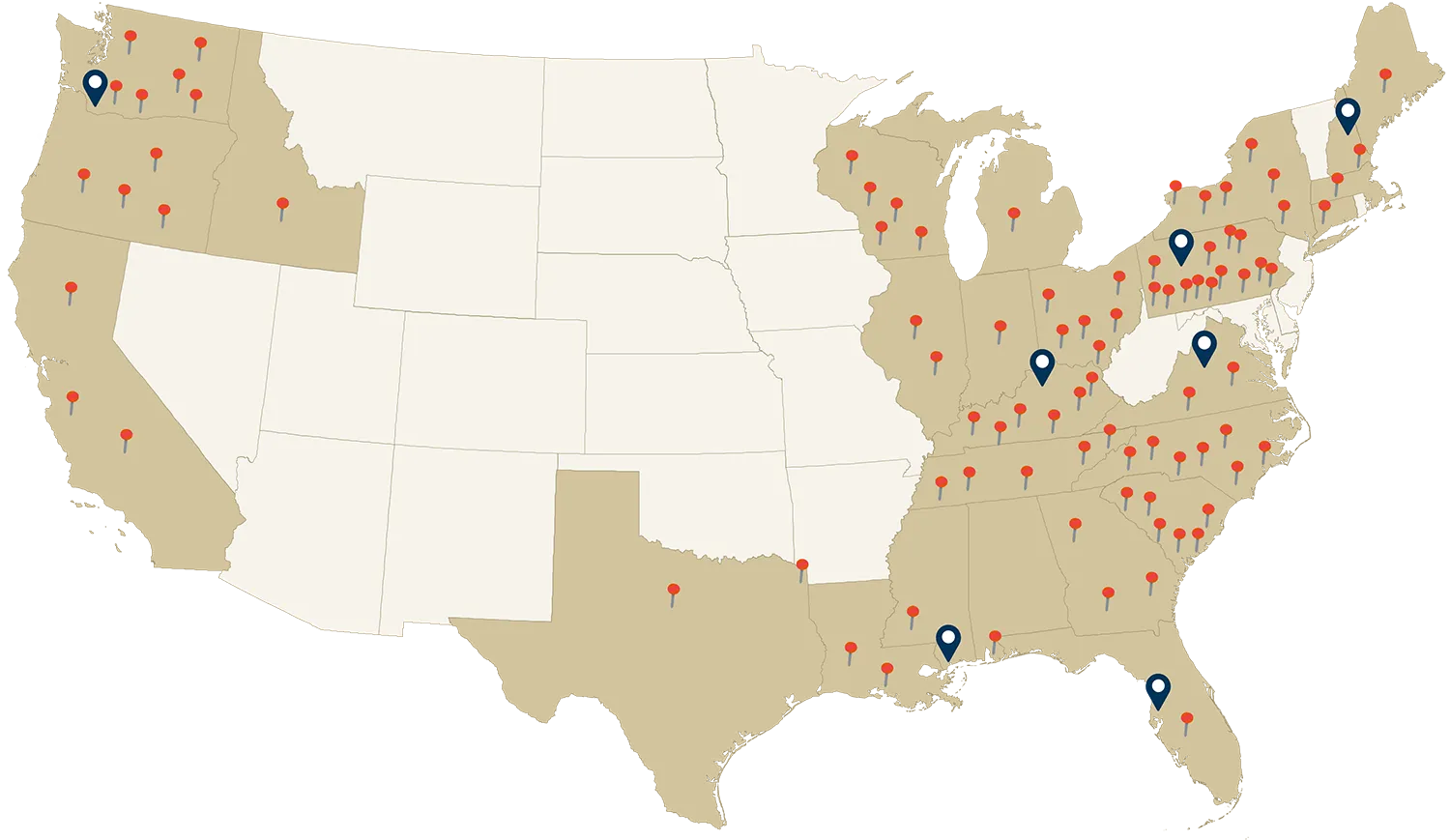

Our LiDAR scanning techs use the latest scanners to accurately collect projects for many reasons. We also have the best team when it comes to processing point clouds. From new installs to Relocations to As builts and profiles Total Precision has a strong team of technicians strategically placed throughout the US to assist you at moments notice.

LiDAR Key Advantages:

How it works:

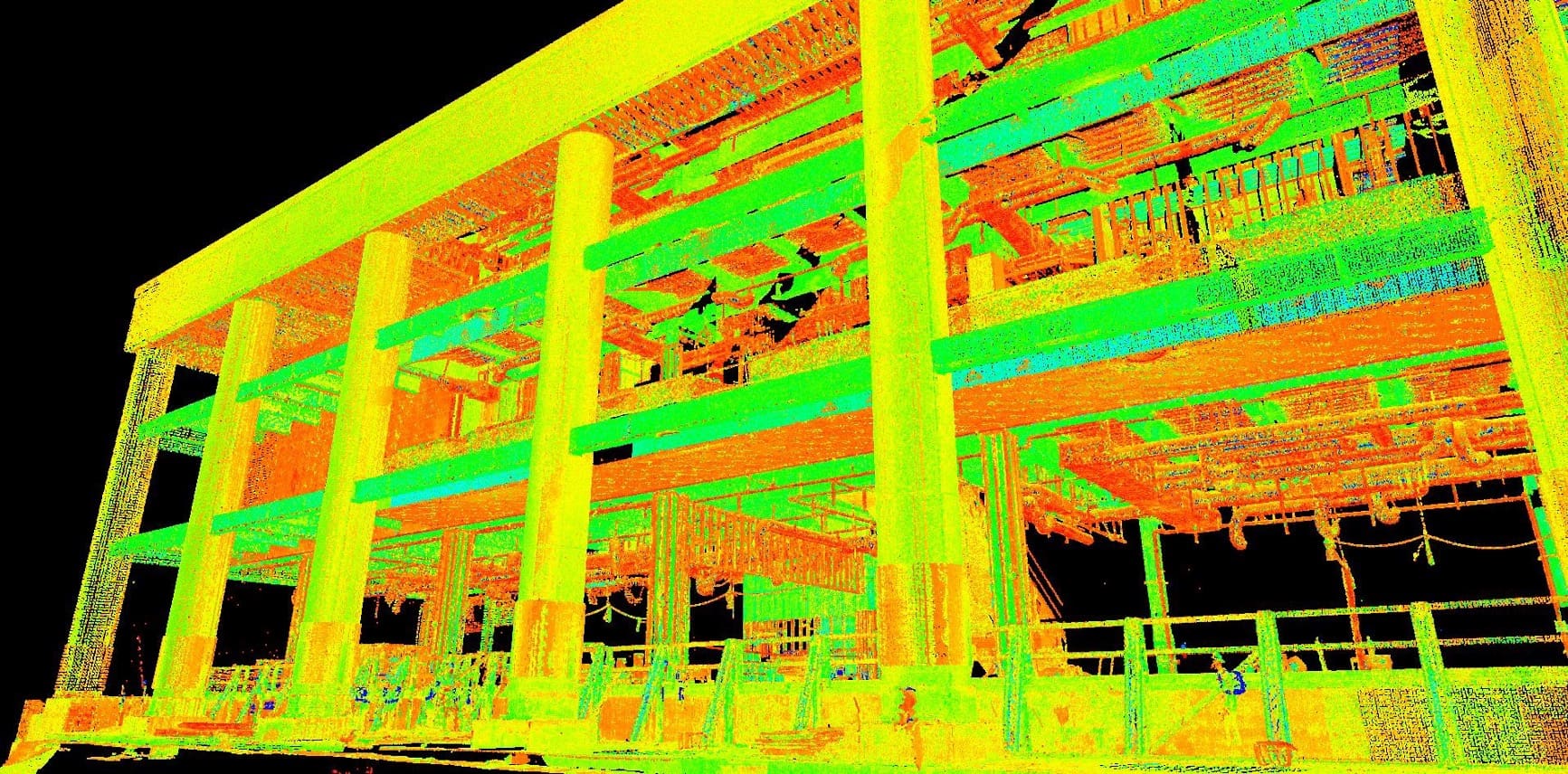

LiDAR devices emit rapid laser pulses—sometimes hundreds of thousands per second—that bounce off surfaces and return to the sensor. By measuring the time it takes for each pulse to return, the system calculates precise distances and creates detailed point clouds (millions of data points) that form a 3D representation of the scanned area.

Light Detection and Ranging (LiDAR) scanning is an advanced survey technology that adds exciting new dimensions to deliverables and applications including as-built surveys, topographic mapping, industrial facilities, settlement, and more. LiDAR scanning allows the modern-day surveyor to collect large amounts of data in a relatively short amount of time, and virtually eliminates the need for additional and costly trips to the project site.

The most important aspect that LiDAR collection brings to a project is the ability to provide a much safer work environment for everyone. This technology allows the collection of a large amount of data with a smaller survey presence on a job. With fewer instrument setups and less climbing, walking, or working in extremely hazardous areas, LiDAR collection truly is the future of all major data collection on projects.

Clients truly benefit from this technology in all aspects. The data that is collected is referred to as a point cloud that can easily be simplified for mapping and modeling of large and complex facilities or made extremely complex for small structural components and machinery. Surveyors collect data in hazardous conditions, confined space areas, with live air, roadway, and rail traffic remotely with no interruption of service.

Because LiDAR collects data at 200,000 points per second, the efficiency combined with the density of data and 3D environment is an overall cost savings for today’s 3D design world.

service related FAQ’s

Yes, LiDAR can help factories reduce energy consumption by creating precise 3D maps of facilities to analyze spatial efficiency, detect insulation gaps, and optimize equipment placement for better energy performance.

LiDAR can assist with predictive maintenance by continuously scanning equipment and infrastructure to detect wear, misalignment, or deformation before problems lead to costly downtime.

LiDAR ensures consistent accuracy, reliability, safety, and data quality across all applications and providers, establishing a strong foundation for professional surveying and construction practices.

LiDAR supports TQM by providing accurate, repeatable measurements that enhance inspection, verification, and quality control across all stages of production and construction.

LiDAR can enhance lean manufacturing by providing precise spatial data that streamlines workflows, reduces waste, and improves process efficiency across your operations.

You can use LiDAR to manage change orders in construction by capturing precise, up-to-date 3D scans of existing site conditions and comparing them to design models or previous scans. This allows you to visually and quantitatively verify scope changes, document progress, and provide defensible evidence for added work or discrepancies—making change order approvals faster, more transparent, and backed by accurate data.

Industry 4.0 uses LiDAR to bridge the gap between traditional surveying methods and modern automation, transforming raw measurements into precise, data-driven insights that enhance accuracy, efficiency, and decision-making.

Factories can enhance product quality using LiDAR by capturing extensive data to verify and ensure measurement accuracy, strengthening quality control and reducing defects in construction components.

We all see things differently, for a variety of reasons. The digital “eye” will consistently see exactly what is there, reducing the impact of human interpretation and delivering objective, reliable data.

Not only does robotics benefit the manufacturing process, it can be an incredible tool to improve the estimate, design, and execution of your project—from initial planning through final delivery.